Introduction

Metal adjustable slide buckles are a foundational component in many industries. From fashion to industrial safety, luggage design to tactical gear, their role is simple yet vital—providing an adjustable and secure way to fasten straps. Built from robust metals like stainless steel, zinc alloy, or iron, and available in numerous finishes, these buckles combine mechanical strength with visual appeal.

In this guide, we explore the various types of adjustable metal strap buckles, their applications, benefits, and what to consider when selecting the right buckle for your product.

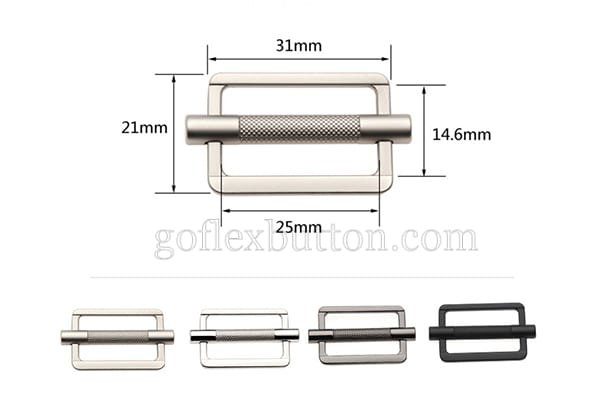

At their core, metal adjustable slide buckles are hardware components that allow for easy length adjustment of a strap or belt. They typically feature a central bar, over which the strap is threaded. This simple mechanism offers quick and secure strap length changes without the need for tools or secondary fasteners.

Unlike plastic buckles, metal versions offer superior durability, better aesthetic value, and longer service life—especially in high-load or outdoor environments. For brands concerned with quality and longevity, metal buckles represent a higher-end choice.

The versatility of slide buckles for webbing makes them a go-to component across various product categories:

Whether you're designing a heavy-duty utility bag or a minimalist fashion belt, the metal strap adjuster buckle offers function without compromising on style.

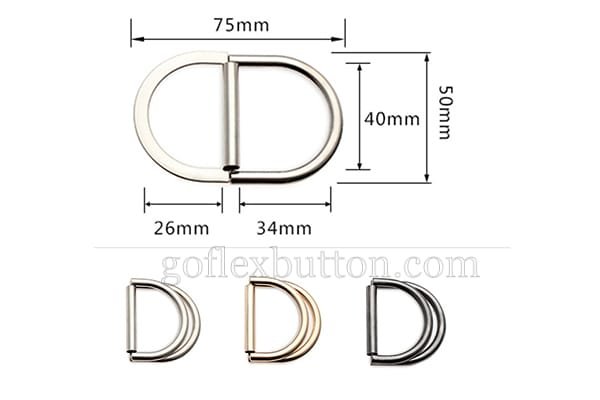

Depending on the application and required load, there are several variations to consider:

When selecting the right metal slide buckles for belts or other applications, consider the following criteria:

For manufacturers or brand designers, the ability to source metal webbing buckles that match product aesthetics and performance is critical. OEMs often require:

Working with a supplier who offers prototyping and sampling for custom metal adjustable buckles can reduce time-to-market and ensure production consistency.

A producer of tactical vests required a heavy-duty metal slide buckle that could withstand over 50kg of load without slipping. After testing both plastic and light-duty metal options, they selected a stainless steel double-bar slide buckle with teeth. This not only ensured high performance but also complemented the rugged aesthetic of their product line.

This example highlights how buckle selection can directly affect product safety, brand perception, and end-user satisfaction.

One of the benefits of using metal adjustable slide buckles is minimal maintenance. However, in environments where moisture or salt is present, corrosion can become a concern. Choosing stainless steel or a quality plating finish will prevent rust and degradation over time.

Regular inspection of the buckle’s grip on the strap is recommended for safety-critical applications like safety harnesses or mobility aids.

Many manufacturers now consider the recyclability of metal strap adjuster buckles in their sustainability planning. Unlike plastic alternatives, metal buckles can be reprocessed or reused at end-of-life, contributing to circular design practices.

For eco-conscious brands, highlighting the use of metal webbing buckles as a sustainable material choice can also add marketing value.

Metal adjustable slide buckles are more than just functional hardware—they are integral to the performance, safety, and design appeal of your product. With their wide-ranging applications, customizable features, and long-term reliability, they remain a staple in countless industries.

Whether you need a lightweight adjustable metal strap buckle for a gym bag, a durable slide buckle metal component for industrial safety gear, or a fully custom metal adjustable buckle for your fashion line, the right buckle makes all the difference.

Take the time to match the right material, finish, and form to your specific use case, and you’ll ensure that your products are not only secure and functional but also built to last.